Brazing Alloy

Brazing Alloy are used to weld items without melting the material of the items, using lead ash.

Brazing Alloy with reliable silver content

Brazing Alloy are used to weld items without melting the material of the items, using lead ash.

Advantages of Brazing Alloy

- 01Clear joint through dispersion

- 02Applicable to precision electronics components of thin film and Fine wire

- 03Applicable to eletric connection and heat exchanger due to its complete heat and electric conductivity.

- 04It is possible to seal to make pressure vessel or vacuum sealing

- 05It makes convenient one-throughput processing for multi-joints.

- 06Step Brazing for complex casting.

- 07Very little chnage of dimension or transformation compared to welding.

- 08Very clear finishing to give second treatments.

- 09Possible to joint different materials, as well as non-metallic component of Ceramic.

- 10It can be melted dependent on the reheating of Brazing part.

Brazing Mechanism

Type of Brazing Alloy

Overview of Copper Brazing Alloy

Phosphate-Copper Filler Metal is a one to decrease the melting point by adding phosphate to copper and having Self Fluxing effect for copper basic material.

It is possible to improve the processing and dispersing capacity, to decrease the melting point, and promote the flexibility by adding Ag and Sn to Copper-Phosphate alloy. So this Phosphate-Copper Filler Metal has good mechanical strength and corrosion resistance that it is

widely used in copper and copper alloy of vessels and heat exchanger.

Alloys and characteristics

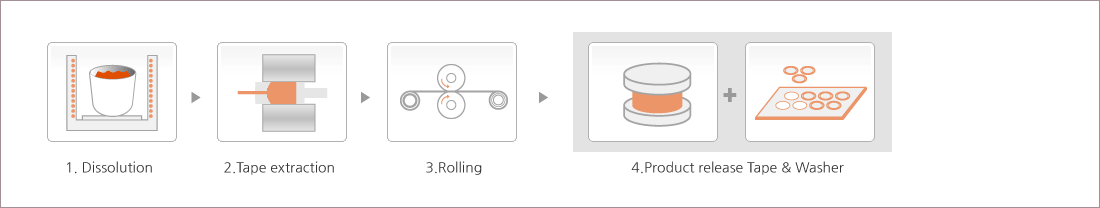

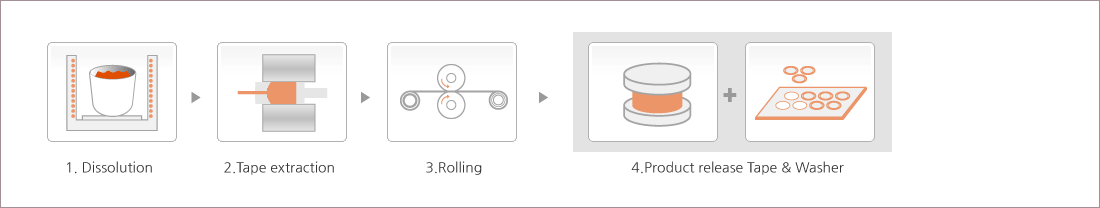

Process

Process for Brazing Alloy Wire

Process for Brazing Alloy Strip